Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Pretreatment Chemicals For Powder Coating

Pretreatment chemicals for powder coating are essential surface preparation solutions designed to clean, degrease, and chemically treat metal substrates before applying powder coatings. These chemicals significantly enhance coating adhesion, corrosion resistance, and overall finish durability, ensuring the long-term performance of your coated products.

Our advanced formulations are tailored for different metal types—including steel, galvanized steel, and aluminum—and are compatible with both manual and automated powder coating lines. With options for environmentally friendly non-chrome treatments, our pretreatment chemicals support compliance with global environmental and safety standards.

Key Features & Benefits

Effective Surface Cleaning

Removes oils, greases, rust, and oxides from metal surfaces. Improves surface energy for better powder adhesion.

Enhanced Corrosion Protection

Forms a thin conversion layer that acts as a barrier against moisture and corrosion. Ensures long-lasting protection, especially in harsh environments.

Compatible with Various Metals

Formulated for aluminum, cold-rolled steel, hot-dip galvanized steel, and other common substrates.

Eco-Friendly Options Available

Chromium-free and phosphate-free solutions available. Compliant with RoHS, REACH, and other environmental regulations.

Optimized for Automation

Suitable for spray tunnel systems, immersion tanks, and manual wipe processes. Stable bath life and easy process control for consistent results.

Pretreatment Process Stages

Degreasing / Alkaline Cleaning

Removes surface contaminants like grease, oil, and dirt.

Advantages

- Improves powder coating adhesion and durability

- Reduces risk of coating defects such as flaking, chipping, and blistering

- Extends corrosion resistance lifespan of finished parts

- Available in concentrated or ready-to-use formats

- Compatible with automatic pretreatment lines and manual operations

Applications

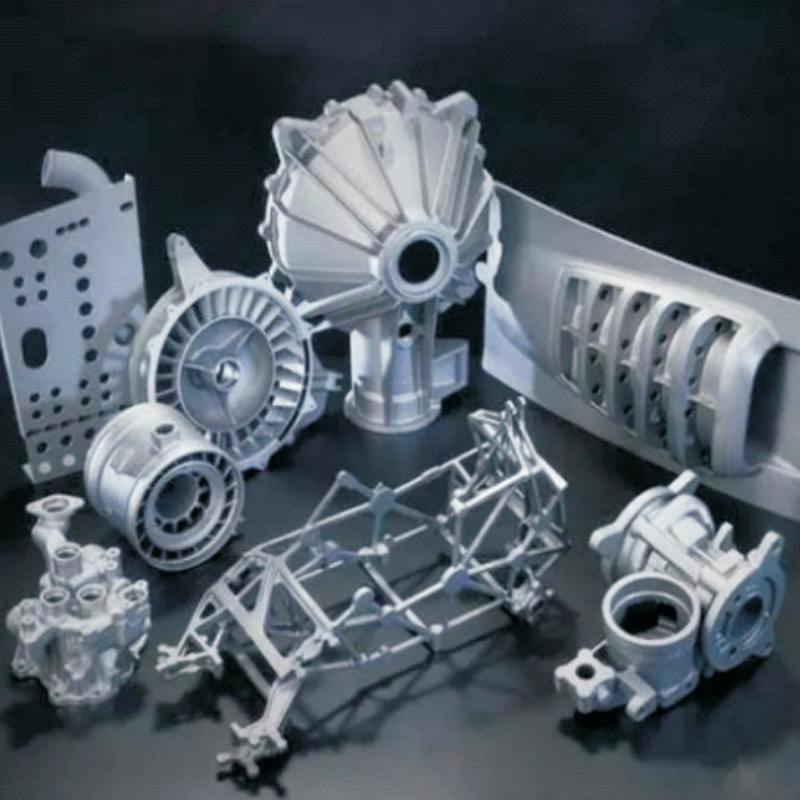

Our pretreatment chemicals are widely used in:

- Architectural aluminum extrusion and curtain wall fabrication

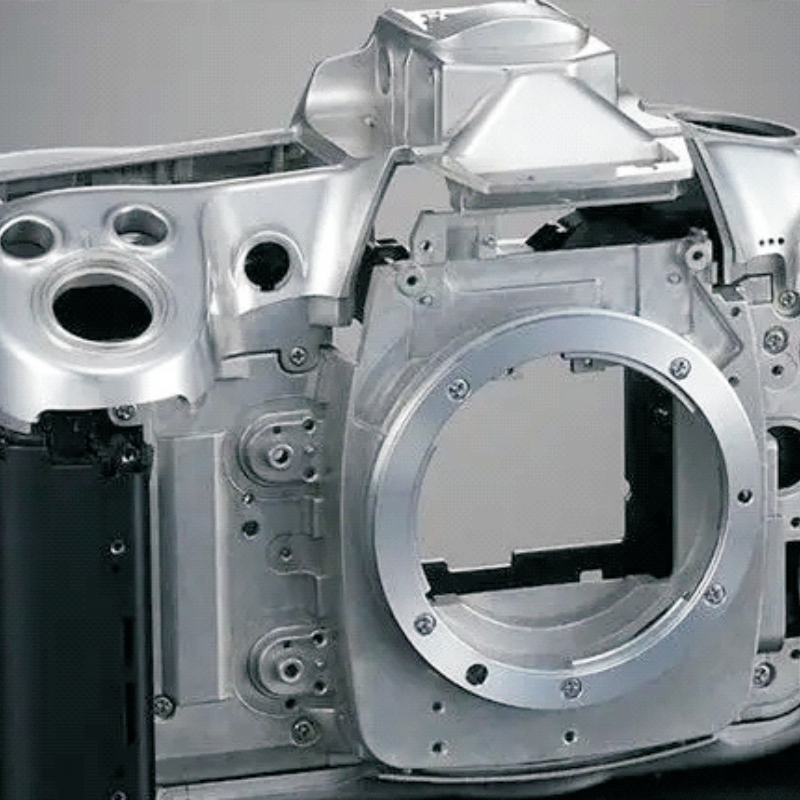

- Automotive parts manufacturing and refinishing

- Home appliances and white goods

- Office furniture and shelving

- Agricultural and construction machinery

- General industrial metal fabrication

Frequently Asked Questions

Q: Why is pretreatment necessary before powder coating?

A: Pretreatment cleans and chemically prepares the metal surface, ensuring strong coating adhesion and long-term corrosion protection. Without it, powder coatings may fail prematurely.

Q: Do you offer chromium-free options?

A: Yes, we offer a full line of non-chrome and eco-friendly pretreatment solutions that comply with global environmental regulations.

Q: Can your products be used in automated spray lines?

A: Absolutely. Our chemicals are designed to be stable and effective in automated spray tunnels, immersion tanks, and manual wipe-down systems.

Q: How can I select the right chemical for my application?

A: Our technical team can help you choose the optimal product based on your substrate material, production method, and performance requirements. You can consult us for the right product.